Choosing the Right Conveyor Roller: What to Look for in a Roller

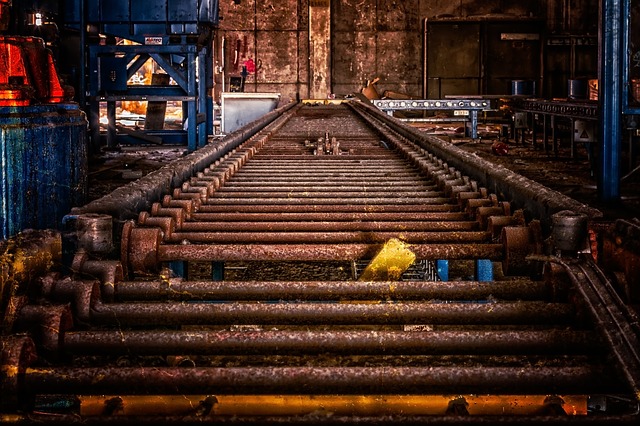

Conveyor rollers are an important component of conveyors in conveyor systems. They are used to roll objects over a distance or via gravity flow of non-supporting material from one point to the next when it isn't necessary to support the movement at any moment along its route.

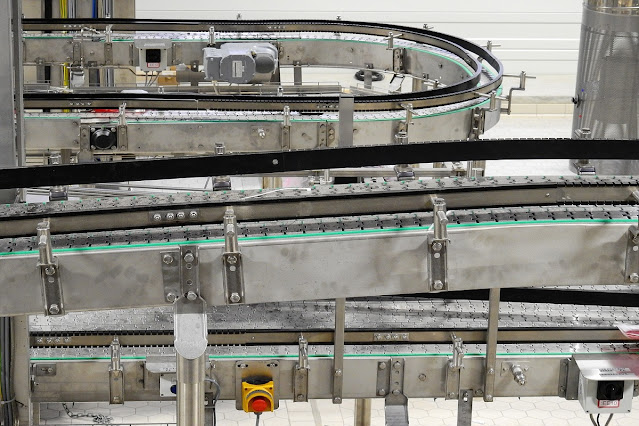

Conveyor rollers must be maintained to function properly. Conveyor roller maintenance will be determined by a variety of factors, including speed, load rating, and application, but all conveyor rollers should be kept clean and well lubricated. Roller bearings should be inspected on a regular basis for wear and replaced as needed because worn-out bearings can cause the roller assembly or even shut down conveyors.

Conveyor rollers come in a variety of shapes and materials, including metal, plastic, and even rubber conveyor roller or conveyor belts. Conveyors should be used for the transportation of things, but other jobs such as vertical stacking conveyors for storage applications may be performed by using conveyor belts or roller assemblies.

Conveyor Roller Selection Criteria

Before you buy a roller conveyor, it's important to understand the criteria that must be met. When searching for the appropriate conveying equipment, you'll come across a variety of different sorts of conveyors with various characteristics and applications. You must know the specific features and selection criteria. The following are some of the things you should include on your list:

(1) Conveyor Roller Dimensions, Width, Length, and Diameter

It's important that conveyor rollers are the appropriate size for conveyors, conveyor belts, and conveyor ramps. The conveyor roller dimensions will be offered by conveyor equipment manufacturers in the user's manual or via a calculation process where all of the conveyor components are taken into account.

Where conveyor rollers are used with flat belts or chains, it is important to consider length, width, span, pitch diameter, and minimum/maximum bend radius. For rubber-covered conveyor rollers check the minimum flexural speed rating versus deflection under load to maintain belt tracking. Conveyors use different types of drive mechanisms that require matching drive wheels to powered equipment specifications.

(2) Conveyor Roller Bearing Type

Conveyor roller bearings are of either the pillow block or mounted bearing type. Mounted conveyor roller bearings (not to be confused with conveyor suspension rollers) are typically steel or nylon and load-rated for conveyors, while pillow block conveyor roller bearings include both single row and double row ball bearings.

Single row conveyor roller bearings use a single retainer to hold the balls in place within the unit (normally mounted on each side), while double row conveyor roller bearings use two retainers; one on each end. There is no difference in the capacity of these units; they normally carry half the load that a double-row design can handle since it has twice as many balls.

Double row conveyor rollers are typically used in higher load conveyor roller applications whereas the single row conveyor rollers are more suited to lower capacity conveyors which have lighter loads up to a maximum of 500 lbs.

(3) Conveyor Roller Load Rating

Conveyor rollers are normally rated for loads up to 500 lbs. Larger conveyor rollers have higher load ratings since larger conveyors need larger conveyor roller bearings. For conveyors that operate at speeds greater than 150 FPM, the conveyor belt conveyor must be equipped with counterweights or an external drive system designed to provide sufficient torque.

(4) Conveyor Roller Style and Materials

Conveyor rollers are made of materials such as metal, rubber conveyors, plastic conveyors, conveyor belt conveyor rollers, and conveyor roller belting.

There are several different types of conveyor rollers to choose from which include steel conveyor rollers, rubber conveyor rollers, polyurethane conveyor rollers, nylon conveyor ball bearings, and urethane conveyor roller belts.

Steel Conveyor Rollers Steel conveyor belts range between 1/8" to 3.15". Metal-trimmed rubber-covered steel conveyors start at 5/16" wide by 2" long up to 1-1/2" X 30". Larger styles are available upon request. In conveyor lines, conveyor roller shafts are available in a variety of materials and diameters from 1/2" to 2".

(5) Distance from Center of Conveyor Roller to Curvature

The conveyor roller curvature as well as the distance from conveyor belt centerline to nearest conveyor roller bearing must be considered since it might interfere with conveyors. In addition, the conveyor's design must match that of the conveyor rollers and conveyor belt; otherwise, problems will result. For example, a rubber conveyor needs a clean and smooth surface and cannot run over debris (sand particles) as steel conveyors can.

If you're designing an industrial conveyance system for bulk material handling or general conveying purposes it's important to know how each component affects overall performance; this is especially true when it comes to choosing conveyors such as rubber-covered conveyor rollers.

Comments

Post a Comment